Product display

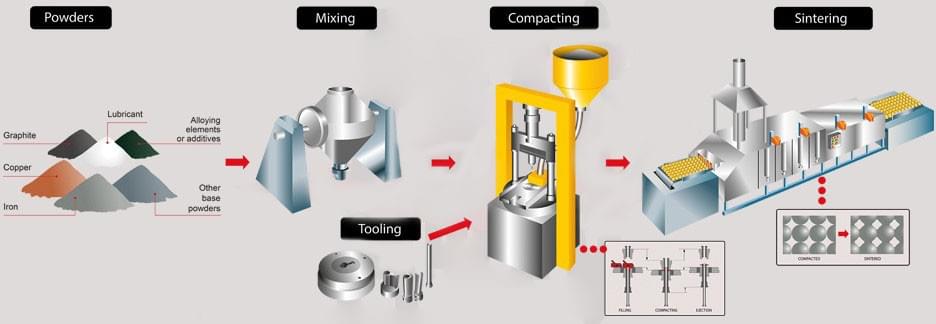

The capital goods industry is a major consumer of sintered parts. Since the profitability of buying sintered parts increases with the annual output, it is easy to understand that the largest consumers are the automotive, electrical appliances and handtool industries and other high-volume industrial segments.

As a reference, each car uses about between 10 and 15 Kg of sintered parts. If an average part weighs 20 grams, this means that each car contains about 600 sintered components, some of which are considered Critical or Safety components.

A wide range of iron-based materials, shapes, finishes, treatments and coatings can be used to obtain parts with high accuracy and performance. Their mechanical properties are comparable to those of wrought structural steels or alloy cast iron, with tensile strength greater than 1,300 MPa being achievable.

Sintering is used to make a great number of mechanical and hydraulic structural components. The main market for sintered components is the automotive industry, which uses powder metallurgy to make an extremely diverse range of structural parts for engines, transmissions, clutches, transfer cases,exhaust, EGR, starters, brakes, steering columns and racks, shock absorbers, comfort and safety systems (rear-view mirrors, sunroofs, HVAC, etc.) and pumps (oil, fuel, water, power steering, servobrake, selective catalytic reduction [SCR], variable valve timing [VVT], continuously variable transmission [CVT], etc.). Other typical markets of sintered components are handtools, household appliances, industrial pumps, home fittings, industrial machinery and weapons.

SHOCK ABSORBER SINTERED PARTS

Piston/Compression seat/Bottom seat/Guider

Shock Absorber Piston

Shock Absorber Foot Valve

Shock Absorber Rod Guider

Shock Absorber Piston

Shock Absorber Foot Valve

Shock Absorber Rod Guider

Pulley

Pulley/Trigger Wheel

Pulley

Trigger Wheel

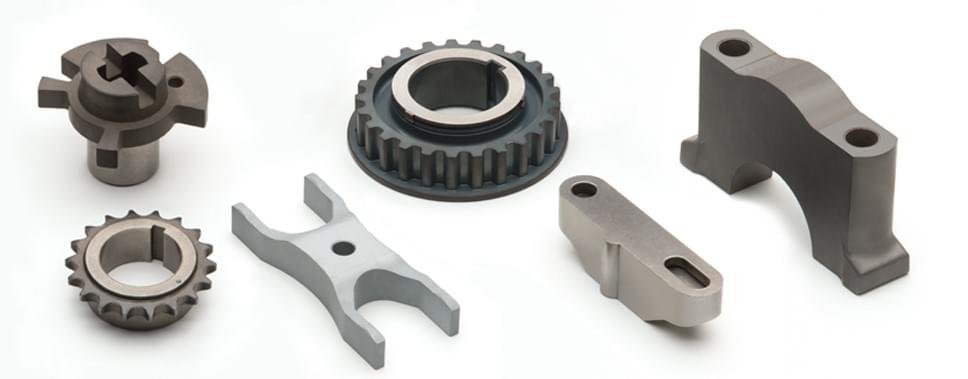

Engine Parts

Sprockets, pulleys, clamps, bearing caps, sensors, couplings.

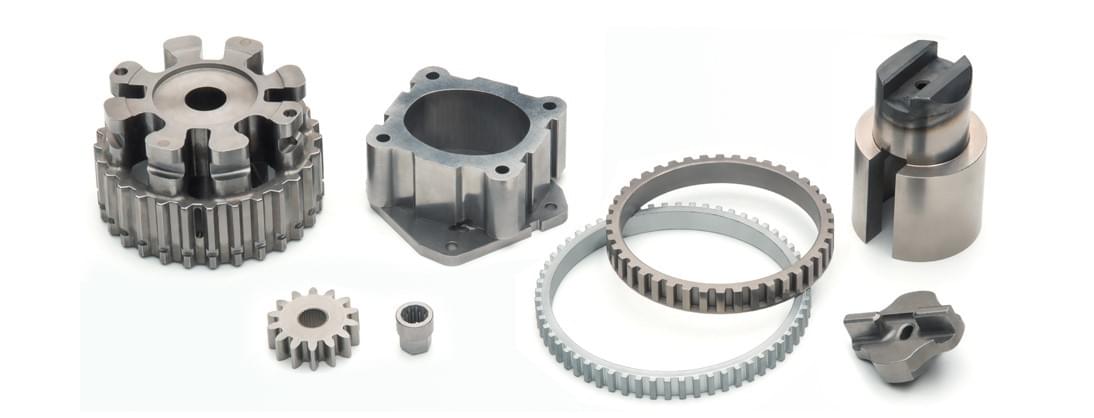

Transmission Parts

Levers, forks, gears, plates, rings and rotors for CVT systems, stoppers. For large components, the Press-Hardening heat treatment allows very hard steels to be formed with minimal dimensional distortion.

Brakes Parts

Rotors, plates, couplings and shoes for servo brake pumps, racks, regulation gears, hubs, ABS sensors.

Streeing Parts

Rotors, rings, plates and sprockets for power steering pumps, rack guides, couplings, gears and racks for locking and adjusting steering wheels.

Unico Auto Parts Ltd.